Introduction

Semiconductors are indispensable in our digital era, and their demand is surging due to the increasing reliance on electronic devices and the pursuit of advanced technology (Read more about semiconductors) . This demand trajectory is expected to continue its upward trajectory. However, semiconductor manufacturing can have significant environmental implications, involving high energy consumption and associated carbon emissions. As we seek to meet the growing semiconductor demand, it is imperative that the industry undertakes measures to mitigate its environmental impact. This entails adopting cleaner, more sustainable practices to align with global commitments, such as the Paris Agreement’s imperative to curb temperature rise not more than 1.5 deg. C.

Semiconductor Manufacturing’s Resource Challenge: A Call for Sustainability

Did you know that semiconductor manufacturing consumes staggering amounts of resources? Semiconductors play a pivotal role in promoting sustainability, but their production process is well-known for its substantial resource consumption. To put things into perspective, a single fabrication plant can devour up to 10 million gallons of water daily, as much electricity as it takes to power 50,000 households every day and produce a staggering 60,000 tons of waste over a year. Therefore, it is important to focus on semiconductor industry sustainability to make this planet safer for tomorrow with sustainable practices.

However, the environmental impact and resource consumption associated with this industry are immense. In order to mitigate these challenges, it is imperative for the semiconductor industry to prioritize sustainability and work collectively towards reducing emissions and optimizing resources. Reducing emissions and optimizing resources in semiconductor manufacturing is an incredibly complex endeavour, marked by numerous facets and a series of interconnected consequences.

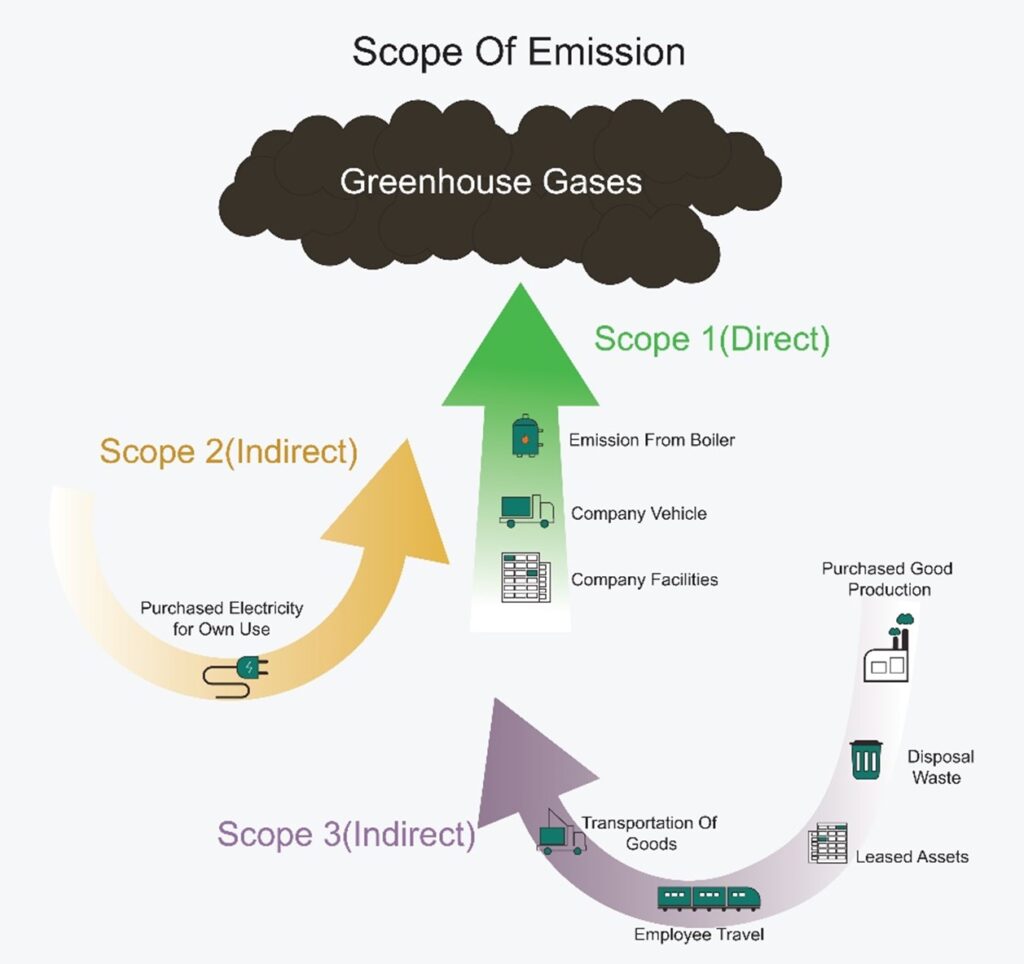

Before we move forward let us understand what are the scope-1 scope-2 and scope-3 emissions. Scope 1 and Scope 2 emissions refer to two different categories of greenhouse gas emissions used in the context of assessing and mitigating environmental impacts:

Scope 1 Emissions

Scope 1 emissions are direct greenhouse gas emissions that result from sources that are owned or controlled by a specific organization or entity. These emissions are produced as a direct consequence of the organization’s activities and operations. Common examples of Scope 1 emissions include emissions from on-site combustion of fossil fuels, such as those produced by company-owned vehicles or the operation of manufacturing processes.

Scope 2 Emissions

Scope 2 emissions are indirect greenhouse gas emissions that arise from the generation of electricity, heat, or steam that an organization consumes but does not produce itself. These emissions are associated with the organization’s energy consumption but are produced by external sources, such as a utility company. They are considered indirect because the organization has control over its energy consumption but not over the emissions produced by the external energy provider.

Scope 3 emissions

It refer to the indirect greenhouse gas emissions that are associated with an organization’s activities but occur from sources that are not owned or controlled by that organization, nor are they included in Scope 2 emissions. These emissions are typically a result of the organization’s supply chain, business operations, and activities outside of its immediate control. Scope 3 emissions are often the largest and most challenging category for organizations to address when it comes to reducing their overall carbon footprint.

The Complexity of Semiconductor Manufacturing

The complexity of semiconductor manufacturing in the context of Scope 1 and Scope 2 emissions is significant. Semiconductor manufacturing is a highly intricate process that involves numerous steps and technologies, and it can have a notable environmental impact due to its resource-intensive nature.

Sources of Scope 1 and Scope 2 emissions in semiconductor manufacturing

sources of emission in scope 1,2 and 3

Energy-Intensive Processes

Semiconductor fabrication facilities, also known as fabs, require substantial amounts of energy to operate. The equipment used for multiple stages like lithography, etching, and deposition demands precise temperature and pressure control, which consumes a significant amount of electricity. Managing the energy consumption and emissions associated with these processes is a major challenge.

Chemical Usage

The production of semiconductors often involves the use of various chemicals, many of which can be hazardous and have environmental implications if not handled and disposed of properly. Managing the procurement, storage, and safe disposal of these chemicals adds to the complexity of the manufacturing process.

Supply Chain Considerations

In the context of Scope 2 emissions, semiconductor manufacturers must consider the energy sources of their electricity providers. The carbon intensity of the electricity grid varies by region and can affect a company’s indirect emissions. Some manufacturers may seek to use renewable energy sources to reduce their Scope 2 emissions.

Global Operations

Most Semiconductor companies often have global supply chains and manufacturing facilities in multiple locations. Each location may have different environmental regulations and standards, which can add complexity to tracking and reducing emissions across the organization.

Evolving Technology

Semiconductor technology is continually advancing, which means that fabs need to keep up with the latest equipment and processes. Transitioning to more energy-efficient manufacturing technologies and processes can be a complex and costly endeavor.

Environmental Regulations

Manufacturers must comply with various environmental regulations and standards, both in terms of emissions and waste management. Meeting these requirements and staying up-to-date with evolving regulations can be a challenging task.

Commitment for Semiconductor Industry Sustainability

- The semiconductor industry has increasingly recognized the importance of sustainability.

- Many individual companies have taken strides to reduce their environmental footprint, both in their manufacturing processes and product design.

Applied Materials

For instance, Applied Materials, a company that provides equipment and services to semiconductor manufacturers, is committed to sustainability. They have set targets to reduce their greenhouse gas emissions, improve energy efficiency in their products, and support their customers in achieving their sustainability goals. 100% of electricity at Applied globally comes from renewable sources by 2030, with an interim goal of 100% in the U.S. by 2022. 50% reduction in Scope 1 and Scope 2 CO2 emissions by 2030. New goal: 55% reduction per wafer of Scope 3 Category 11 emissions by 2030

Intel

Intel, one of the world’s largest semiconductor manufacturers, has made significant commitments to sustainability. They have set a goal to achieve 100% renewable energy use across their global operations and have invested in on-site solar power and wind energy. They also aim to achieve net-positive water use by 2030 and are actively involved in reducing emissions in their supply chain.

TSMC

TSMC (Taiwan Semiconductor Manufacturing Company) is a major semiconductor foundry. They have committed to achieving carbon neutrality by 2050. They are investing in energy-efficient equipment, transitioning to renewable energy sources, and participating in global initiatives like the RE100 campaign, which encourages the use of 100% renewable energy.

Samsung Semiconductors

Samsung Semiconductor has set ambitious sustainability goals, including using 100% renewable energy in its facilities in the United States, Europe, and China by 2020. They have also introduced eco-friendly packaging for their products and are actively working to reduce emissions in their manufacturing processes.

GlobalFoundries

GlobalFoundries is another significant semiconductor manufacturer. They have launched their “GlobalFoundries for Good” program, focusing on environmental sustainability, employee well-being, and community engagement. They are investing in renewable energy and energy-efficient technologies to reduce emissions.

NVIDIA

NVIDIA known for its graphics processing units (GPUs), is dedicated to reducing its carbon footprint. They have committed to 100% renewable energy for their global operations and have invested in energy-efficient data centers to reduce emissions associated with their products.

These examples showcase how semiconductor companies are taking tangible steps to address sustainability challenges. They are investing in renewable energy, reducing emissions, and adopting environmentally responsible practices to contribute to a more sustainable future while meeting the increasing demand for semiconductor products.

How to approach semiconductor industry sustainability

Semiconductor companies are taking various approaches to tackle Scope 1 and Scope 2 emissions as part of their sustainability and environmental initiatives. Here are some common semiconductor industry sustainability plans and actions they are implementing:

Energy Efficiency Improvements

Semiconductor manufacturing is energy-intensive, so companies are investing in energy-efficient equipment and processes. This includes upgrading manufacturing equipment, optimizing cleanroom operations, and implementing advanced cooling and heating systems to reduce energy consumption and associated Scope 1 emissions.

Renewable Energy Adoption

Many semiconductor companies are transitioning to cleaner energy sources to power their manufacturing facilities. This may involve installing solar panels, wind turbines, or purchasing renewable energy certificates (RECs) to offset their electricity consumption. Shifting to renewables helps reduce Scope 2 emissions.

Green Building Practices

Companies are designing and constructing energy-efficient and environmentally friendly facilities. This can involve LEED (Leadership in Energy and Environmental Design) certification, which promotes sustainable building and development practices.

Process Innovation for Semiconductor Industry Sustainability

Semiconductor manufacturers are constantly developing more efficient and environmentally friendly manufacturing processes. This includes researching and implementing new materials, chemicals, and technologies that reduce emissions and waste during fabrication.

Carbon Offset Programs

Some semiconductor companies participate in carbon offset programs to neutralize their emissions. This involves investing in projects that remove or reduce an equivalent amount of greenhouse gases from the atmosphere, such as reforestation or renewable energy projects.

Supply Chain Engagement

Semiconductor manufacturers are collaborating with their suppliers to reduce emissions within the supply chain. This can include encouraging suppliers to adopt sustainable practices, source materials responsibly, and reduce transportation-related emissions.

Monitoring and Reporting

Companies are implementing robust monitoring and reporting systems to track their emissions accurately. This helps them identify areas where emissions can be reduced and ensures compliance with emissions reduction targets and reporting requirements.

Energy Management Systems

Implementing energy management systems (EMS) helps semiconductor companies optimize energy use, identify energy-saving opportunities, and monitor performance in real-time.

Corporate Social Responsibility (CSR)

Many semiconductor companies are integrating environmental sustainability and emissions reduction goals into their CSR programs. This includes setting targets for reducing both Scope 1 and Scope 2 emissions and transparently reporting progress.

Government Incentives for Semiconductor Industry Sustainability

Some semiconductor companies take advantage of government incentives and subsidies to adopt clean energy practices, which helps cut emissions costs. These firms are increasingly aware of the need to address Scope 1 and 2 emissions to align with global sustainability goals, potentially enhancing operational efficiency and reducing long-term energy expenses. However, Scope 3 emissions pose significant challenges, making it challenging to achieve net-zero emissions by 2050.

The Complexity of Scope 3 Emissions for Semiconductor Industry Sustainability

- Addressing scope 3 emissions presents a unique challenge for the semiconductor industry sustainability.

- Scope 3 emissions refer to indirect emissions caused by activities that are not under direct control but are associated with the value chain of a product or service.

- In the case of semiconductor manufacturing, collaborating with partners, suppliers, and customers becomes crucial in reducing scope 3 emissions.

- The challenge then lies in identifying and defining impactful actions that involve all stakeholders.

- The issue becomes one of supply chain transparency, as each link in the value chain must make efforts to measure, report, and reduce emissions collectively.

- In particular, decarbonization in the semiconductor industry is not merely a matter of reducing emissions within manufacturing facilities; it involves the cumulative impact of the entire supply chain and the lifecycle of the products.

The consensus for semiconductor industry sustainability

There is now a widespread consensus within the industry regarding the imperative to infuse sustainable practices into semiconductor production, especially considering the industry’s forthcoming expansion. Furthermore, individual companies are taking proactive measures. As highlighted above, Applied Materials has made substantial strides in shrinking our carbon footprint and transitioning to greater reliance on renewable energy sources. For the semiconductor industry sustainability, other industry participants such as TSMC , GlobalFoundry, Intel, STMicro are similarly committed to curbing their Scope 1 and Scope 2 emissions (those originating from a company’s operations and energy consumption.

“The good news is that our skills and knowledge are harnessed to propel captivating innovations within semiconductor technology. Moreover, these very capabilities hold a pivotal role in comprehending the intricacies associated with constructing a more environmentally sustainable industry. In particular, cultivating a mindset that allows us to discern the implications of our present actions on our overarching, future objectives becomes essential. This frame of mind serves as the cornerstone for monitoring our advancement across time and ensuring that accountability is shared among all stakeholders.”

Priority Areas for Semiconductor Industry Sustainability

Now, let’s explore three priority areas that need attention for sustainable semiconductor manufacturing.

Energy Efficiency in Manufacturing Processes:

- Implement energy-efficient manufacturing processes and technologies.

- Optimize equipment and machinery to minimize energy consumption.

- Utilize advanced cooling systems to reduce energy-intensive heat dissipation.

- Invest in renewable energy sources, such as solar or wind, to power manufacturing facilities.

Supply Chain and Raw Materials:

- Assess and reduce the carbon footprint of raw materials used in semiconductor production.

- Collaborate with suppliers to source materials with lower emissions.

- Promote sustainable mining and extraction practices for essential materials like rare earth elements.

- Streamline supply chain logistics to reduce transportation-related emissions.

Design for Sustainability:

- Develop semiconductor products with lower power consumption.

- Create energy-efficient chips and devices that consume less electricity during use.

- Implement product design strategies to prolong the lifespan of semiconductor devices, reducing the need for replacements.

- Encourage the recycling and reuse of semiconductor components and materials.

Scope 3 Emissions Reduction:

- Collaborate with industry partners, suppliers, and customers to address Scope 3 emissions.

- Identify and mitigate emissions generated throughout the semiconductor value chain.

- Promote transparency and disclosure of emissions data to track progress.

- Explore innovative solutions for reducing emissions in transportation, manufacturing, and product usage.

Conclusion

Semiconductor manufacturers are grappling with a substantial responsibility as they confront a multitude of challenges that often fall outside their direct sphere of control. The semiconductor sector is under increasing pressure to decarbonize, and the industry has a track record of facing persistent and complex issues upstream. In this evolving landscape, chip manufacturers can no longer simply pass the buck when it comes to emissions in their supply chains. Market leaders must proactively take steps to distinguish themselves by establishing environmentally friendly supply chains. This approach is not only beneficial for their own competitiveness but is also the essential path towards achieving sustainability in the semiconductor industry.

Closing Thoughts

- Express optimism about the potential for the semiconductor industry to transform into a more sustainable and environmentally responsible sector.

- Encourage readers to explore further resources and articles on sustainable manufacturing.

- Provide links to relevant content for readers to delve deeper into the topic and discover additional insights.

0 Comments